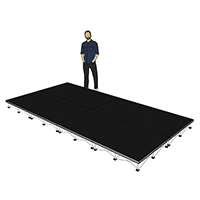

Modular Stage

Performance areas rarely stay the same for long. One evening the space accommodates a classical quartet, the next it hosts a lively drama workshop, and by the weekend, it supports a keynote speech. A modular stage provides the adaptability needed for such varied timetables, allowing venues to reshape the floor plan without building work or lengthy change-overs. Below, the essential features, design considerations and typical applications of contemporary systems are explored in detail.

The Modular Principle

A stage built from modules relies on individual panels that lock together, forming a continuous surface. Because each panel conforms to standard dimensions, any configuration remains compatible with the next. The concept sounds simple, yet the engineering behind a dependable modular stage system is anything but basic; tolerances must be tight, fixings secure, and surfaces true to guarantee a safe working platform at every event.

Modular Stage System Core Components Explained

Although models differ between manufacturers, most systems share three main elements:

- Deck sections: The visible platform surface where performers, lecterns or scenery sit. Each modular stage platform is built to resist flex while remaining light enough for manual handling.

- Support frames: Integrated legs or separate under-structures distribute loads evenly and maintain level alignment across the entire build.

- Joining hardware: Clever couplers pull adjoining panels tight, removing gaps and preventing lateral movement once assembled.

Portable Modular Stage Options

Moving a stage from hall to hall, or loading it into a van for an off-site show, calls for lighter framing and compact storage. A portable modular stage addresses these demands through aluminium skeletons, folding legs or trolley-compatible designs. Weight is shaved wherever possible, yet manufacturing standards still provide the load ratings expected in professional environments such as colleges, touring productions or council facilities.

Demountable Staging for Fast Turnaround

Shared venues often face tight schedules; in such cases demountable staging keeps downtime to a minimum. Quick-release features let small crews dismantle large runs in minutes, clearing the floor for alternate activities. Because the same elements can be carried through doorways or stored vertically against a wall, multi-function spaces regain square footage without permanent fixtures getting in the way.

Designing Creative Modular Stage Sets

Not every performance requires a flat rectangle. Tiered levels, run-around walkways or thrust sections all play a part in production design. With modular stage sets, inventive shapes are achieved by mixing straight panels, corner pieces and variable leg heights. Directors and event planners gain freedom to experiment, knowing alterations can be reversed or modified for the next booking without investing in new stock.

Modular Stage Platform Factors to Consider

- Load rating: Specified in kilograms per square metre; always choose a system that exceeds the heaviest expected duty.

- Surface finish: Carpet, textured phenolic coating or hard-wearing paint each bring different acoustic and grip properties.

- Edge safety: Bevelled borders minimise trip risk and create tidy junctions with floor coverings.

- Fire performance: Many venues insist on Class 1 or Class B materials for compliance with local safety codes.

Storage and Logistics

A modular system is only as convenient as its handling process. Proper flight cases or purpose-built carts prevent damage, keep sections organised by size, and streamline transport between store and stage. Panels slot upright or flat, depending on the trolley design, helping technical staff load trucks quickly when visiting satellite sites.

Typical Sectors Making Use of Modular Staging

- Schools and academies

- Regional theatres and art centres

- Community halls and civic buildings

- Corporate meeting suites

- Places of worship

- Outdoor festivals and seasonal fairs

Working with Specialist Suppliers

Engaging a supplier that focuses on live production infrastructure brings advantages beyond a simple sale. Detailed drawings, weight calculations and on-site demonstrations shorten the learning curve for caretakers or stage managers. After-sales support, spares availability and refresher training further increase system longevity.

Maintenance Snapshot

- Inspect locking points before every build.

- Clean panels with mild detergent; avoid solvents that may compromise coatings.

- Store in dry areas, raised from damp floors.

- Replace fasteners showing corrosion or thread damage.

Summary

From intimate recitals to full-scale conferences, a well-chosen modular stage brings clarity, safety and operational flexibility to any venue schedule. Through careful selection of compatible panels, portable framing and adaptable accessories, facilities gain a long-term solution that evolves with programming needs.