Stage Legs

Every temporary performance area relies on an invisible hero: the legs that hold the structure steady. Well-chosen stage legs stop movement, resist vibration and give performers absolute confidence underfoot. The following guide looks at the role these components play, the variations available and the practical points that affect day-to-day work in theatres, touring productions, broadcast studios and community halls.

What Stage Deck Legs Actually Do

In practical terms a leg is little more than a rigid tube with a connection at one end and a foot at the other, yet its job is far from simple. It must:

- Transfer loads straight to the ground without twist.

- Keep the deck section perfectly level with its neighbours.

- Absorb occasional horizontal force from energetic movement or rolling flight-cases.

- Cope with uneven flooring, temperature change and repeated assembly.

Meeting these demands calls for accurate machining, quality alloys or steel and a secure locking method between the leg and the deck frame.

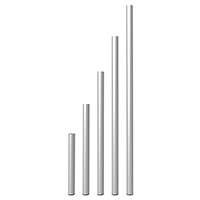

Fixed Length Legs

Fixed units come in a series of standard heights, often 200 mm, 400 mm, 600 mm and 800 mm. With no moving parts they bring maximum rigidity and minimal maintenance. Many installers keep a full set in each height for programmes that never change layout.

Adjustable stage legs

A telescopic tube inside a tube provides variable height with centimetre-level accuracy. Graduated markings or digital scales on the outer wall make it easy to match one leg to the next. A compression collar, locking pin or handwheel then clamps the inner section in place. Adjustable sets prove invaluable on raked theatre floors or outdoors where paving slabs, astro-turf and natural ground seldom line up.

Portable stage legs

Rental firms and touring crews favour lightweight options that pack neatly in trunks. Anodised aluminium is typical; it resists scuffs, weighs less than steel and handles the condensation that occurs when equipment moves from cold lorries into warm venues.

Material Choices

- Aluminium alloy – excellent strength-to-weight ratio, naturally corrosion resistant, easy to handle single-handed.

- Mild steel – heavier but unbeatable in ultimate load rating, often protected with hard powder-coat for long service life.

- Composite feet – nylon or high-impact polymer inserts prevent paint transfer onto polished floors and add grip on concrete.

Assembly Advice

Putting the structure together takes little time when a clear routine is followed:

- Lay the deck sections upside down on flat ground for easy access to the sockets.

- Insert each leg fully, checking that collar or spring pin snaps home.

- Flip the deck with two crew - never twist one corner up first.

- Bring adjoining sections together and link them with the chosen bracket system.

- Stand back and sight along the top surface; adjust telescopic legs or levelling feet until every seam disappears.

Routine Inspection

Though simple equipment, legs deserve a quick check each time they return from hire or tour:

- Look for deformation in the tube - especially crush marks from over-tight straps.

- Spin the locking collar; it should feel smooth with no gritty spots.

- Examine the rubber or nylon foot for splits. A missing pad ruins polished flooring and invites complaints from venue managers.

Common Slip-ups

- Mixing metric and imperial tube diameters which leads to sloppy joints.

- Using makeshift spacers or blocks to overcome an uneven surface rather than choosing an adjustable model.

Advantages Summarised

A single component delivers several wins:

- Fast build and break-down saves labour cost on tight turnarounds.

- Modular heights allow tiered layouts for sightlines or camera angles.

- Precision engineering guarantees rock-solid feel under dance moves, choirs or orchestras.

- Compact footprint inside flight-cases keeps lorry space free for scenic elements and lighting bars.

Longevity and Care

With basic housekeeping these legs last for years. After each use wipe away tape residue and road dirt. Avoid oil sprays unless the maker recommends them as oil attracts grit that chews through threads. Store vertical when possible; leaning heavy tubes horizontally on pallets encourages bending during transport.

Buying From a Specialist

Stage Concepts stocks a broad catalogue of stage deck legs in fixed, adjustable and portable forms. Compatibility notes on each page reference the major European deck brands. Orders placed before midday normally leave the warehouse the same afternoon, and technical staff are on hand to confirm tube diameters, load ratings or to quote for custom lengths.

Checklist Before Ordering

- Deck system make and model.

- Preferred working height in millimetres.

- Maximum distributed weight anticipated.

- Indoor, outdoor or mixed use.

Answering those four points ensures the correct set arrives first time, eliminating delays on production schedules.

Unexpected Uses

While designed for performance decks, identical legs often appear beneath tradeshow plinths, drum risers or camera risers and dolly platforms. Their proven capacity and quick locking action translate well into any field that needs a rigid elevated surface.