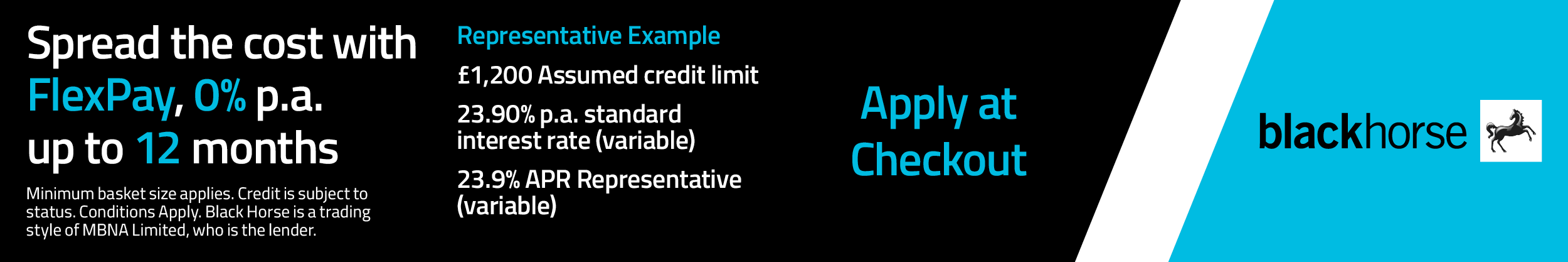

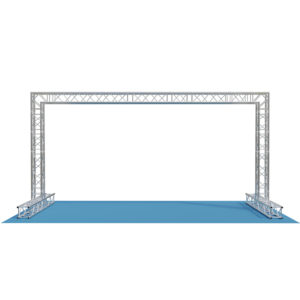

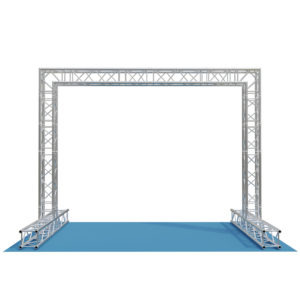

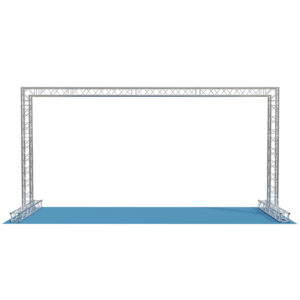

Video Wall Truss

Portable and modular truss systems for suspending LED video walls. Constructed using our quad truss from Alustage, our video wall truss systems are extremely durable with superior weight loading and anti flex properties.

Easy to construct and break down using industry-standard pins and spigots with pontoon footings for ample surface contact to prevent tilting and leaning. Our ready to use systems are suitable for both indoor and outdoor use.

2 Years Warranty

2 Years Warranty 60 Day Returns

60 Day Returns