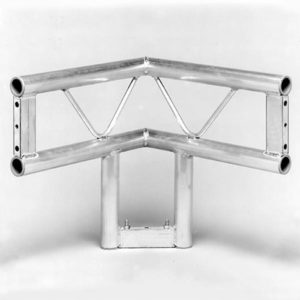

SC Pro SS Ladder truss

When loading and maximum clear span are less important than appearance and storage space, then ladder truss (or SST - "Single Sided Truss") is the way to go. Both full truss junctions and alternative, lower-cost options are available for this format, and lifting eyes, single pole uprights and adaptors to take full truss uprights are also offered.

With a clear span capability of up to 8m, typical applications for SST include lighting grids and exhibition or retail structures where both display and storage space is at a premium.

2 Years Warranty

2 Years Warranty 60 Day Returns

60 Day Returns