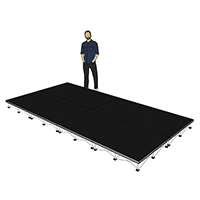

Stage Units

Reliable performance spaces rarely happen by accident. They are planned, constructed, and refined using components that cope with busy schedules, frequent re-configurations, and strict safety checks. Stage units sit at the centre of that process. Unlike fixed builds, these prefabricated modules are carried in, locked together, and packed away again without fuss. The result is a raised surface that feels permanent while remaining completely movable.

Adaptability Becomes the Standard

Few modern venues host a single activity. A hall might hold a conference on Monday, an awards evening on Thursday, and a play at the weekend. Stage units cope with these changes by allowing crews to alter width, depth, or shape on demand. Straight lines, L-shapes, curves—virtually any footprint is possible when individual blocks are linked in different patterns. Taller elements can be added in select positions to introduce visual tiers, or an entire formation can sit at a single height for simplicity.

Storage between events is equally uncomplicated. Units nest or stack to minimise the room required in backstage cupboards or equipment cages, protecting the walking surfaces from damage while they wait for their next assignment.

Material Choices and Surface Finishes

Selecting the correct surface affects both longevity and day-to-day practicality. Most decks employ multi-layer birch ply finished with a durable phenolic coating. The material resists chipping, delivers consistent traction, and shrugs off the scratches that naturally occur during fast changeovers. Composite boards—often a blend of glass fibre and resin—offer even greater water resistance where humidity or occasional spills could become an issue.

Aesthetic considerations matter as well. Neutral black keeps attention on the performers, while mid-tone greys integrate with corporate branding. Carpet overlays remain popular in venues where speakers prefer a softer footing or where acoustic dampening helps control room reflections.

Compliance Is Non-Negotiable

Public events fall under demanding legislation. Every item used in the build must meet recognised standards for load capacity, fire reaction, and slip resistance. Quality manufacturers back their stage units with independent test certificates, giving venue managers documented proof that the equipment can stand up to repeat use.

- Certified weight ratings protect against structural failure.

- Fire-retardant deck materials reduce risk in crowded areas.

- High-contrast edging options help presenters locate boundaries under bright lighting.

Portable Stage Units for Fast Turnaround Sites

A touring company, a hire depot, or a secondary school timetable rarely allows long installation windows. Portable stage units address that challenge by stripping complexity from the process. Frames fold or detach in seconds, captive fasteners stay with the component—so nothing goes walkabout—and lighter alloys reduce handling strain. Even a small crew finds it possible to configure a workable platform during a single rehearsal break.

When the event finishes, the same units come apart just as quickly. Components slide into wheeled carts or custom dollies, passing through standard doorways without drama. The efficiency created by this cycle improves venue utilisation and lowers staffing costs—an instant advantage for busy schedules.

Durability in High-Traffic Environments

School halls and public theatres push equipment hard. Heavy scenery, rolling cases, and constant footfall combine to test joints and surface coatings daily. Premium manufacturing techniques counteract that wear. Anti-corrosion treatments lock out moisture, and robust powder coats resist chipping. Screws employ locking threads to stay tight after repeated vibration, while non-marking feet preserve delicate floor finishes beneath the structure.

Little touches contribute to a longer service life, too. Rounded edges protect fabrics during quick drape changes, and recessed hardware avoids scratch lines in storage. By minimising repair intervals, venues keep more of their budget for creative projects rather than replacement stock.

Maintenance Without Mystery

Day-to-day care remains straightforward. A visual sweep before each build identifies loose fasteners or dented panels. Tightening bolts with a standard spanner or replacing a damaged deck rarely takes more than a few minutes. Periodic deep checks—scheduled during quieter periods—ensure compliance documents stay current.

- Keep joints clear of grit to preserve smooth engagement.

- Store units in dry conditions to avoid frame corrosion.

- Record inspection dates for insurance and licensing bodies.

Specification Checklist

An informed purchase starts with a concise brief. The checklist below outlines the core points specifiers generally review before committing funds:

- Maximum Audience Load – calculate worst-case numbers to ensure adequate capacity.

- Deck Size Options – confirm standard module dimensions match doorways and lifts.

- Height Variations – decide whether fixed levels suffice or adjustable legs are essential.

- Compatible Accessories – railings, steps, lighting bars, or valance fittings.

- Storage Footprint – assess backstage space to avoid congestion.

- Assembly Time – gauge crew availability versus installation windows.

Budget and Procurement Guidance

Capital expenditure for performance infrastructure can appear daunting, yet considering lifetime cost paints a different picture. Quality stage units easily outlive several sets of flooring or seating, especially when routine upkeep is scheduled. Leasing packages and serviced hire agreements also exist for organisations preferring predictable monthly figures over upfront spending. Independent advisors can help weigh these models against long-term ownership, factoring in the frequency of changes and the value of in-house flexibility.

Lead times vary. In-stock ranges ship rapidly, while customised finishes or unusual deck sizes require a short production window. Open communication with suppliers prevents scheduling surprises and makes integration with lighting or audio upgrades far simpler.

Real-World Application Scenarios

The principles above translate into a broad set of uses: a lecture theatre wanting extra presentation space during examination periods; a town hall hosting a classical recital one evening and a charity auction the next; a studio building temporary camera risers on location. In every case, the same core features—strength, adaptability, ease of handling—allow crews to concentrate on the artistic or commercial objectives rather than the mechanics beneath them.

Future-Proofing Through Modular Expansion

Venues change. Pop-up productions grow in popularity, or an institution receives funding to widen community engagement. A key benefit of investing in a module-based approach is the ability to expand capacity without redundant spending. New units purchased years later still connect to the existing stock, safeguarding the original investment and supporting audience growth.

Conclusion

Stage units blend permanence with freedom. They provide the solid footing that performers expect, while remaining nimble enough to follow an ever-shifting events calendar. Through thoughtful design, sensible material choices, and rigorously tested connections, these modules deliver a professional surface wherever they travel. Whether the requirement involves compact portable stage units for a touring troupe or a larger semi-permanent array inside a municipal auditorium, the guiding principles stay the same: safety, strength, and straightforward handling.