Heavy Duty Stage Ramps

Event production relies on smooth and secure access routes. Heavy duty stage ramps deliver that link between ground level and the elevated performance space, ensuring safe transfer of people, instruments, flight-cases, and general kit. They sit alongside stage platforms as an indispensable component of the modern venue, whether installed permanently or touring from city to city.

Why Heavy Duty Construction Matters

Regular ramps often fall short when confronted with constant loading, rolling castors, and the high live loads associated with professional shows. A heavy-duty approach adds extra margin through reinforced frames, thicker profiles, and surface treatments that shrug off knocks, moisture, and repeated setup cycles. In practice, that translates into fewer maintenance stoppages and a lower lifetime cost.

Key Characteristics

- Certified load ratings that accommodate large static and dynamic weights

- Stable geometry, allowing consistent slopes, safe toe clearance, and firm landings

- Integral or bolt-on handrails for crowd, performer, and crew assurance

- High-traction surfaces - Natural ply anti-slip finishes and Hexa surfaces

- Connection plates that interface precisely with existing stage platforms

Load Capacity in Real Terms

Most professional heavy-duty stage ramps fall within 500 kg to 2,000 kg uniform distributed load. Higher ratings exist for broadcast trucks or set pieces built on steel frames, so specifications must consider the heaviest likely case rather than the average. A track for motorised scissor lifts, for instance, demands an additional safety margin over a walkway used only by cast and crew.

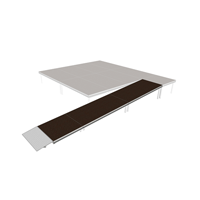

Balancing Slope and Length

Slope dictates comfort and regulatory compliance. In the UK, a 1:12 gradient frequently meets accessibility guidance for wheelchair access; however, quick turnaround productions sometimes accept a steeper incline for flight-cases when staffing levels guarantee controlled movement. Whenever the footprint of a venue restricts ramp length, modular extensions or switch-back layouts can restore a gentle rise without expanding beyond available floor space.

Surface Treatments and Traction

Grip stems primarily from surface texture—chequer-plate, serrated bar grating, or high-grade non-slip tapes. A secondary line of defence comes from drainage slots that prevent puddling and ice formation. Selecting a finish must account for footwear types: dancers' soft soles, technician boots, and mobility tyres all behave differently. Durable coatings avoid loss of texture under abrasive stage traffic.

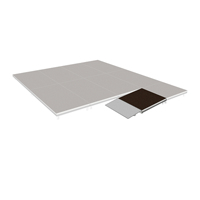

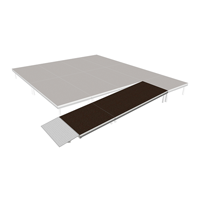

Compatibility with Stage Platforms

Stage manufacturers tend to follow a modular logic: fixed deck heights in 200 mm increments, common bolt patterns, and standard edge profiles. Heavy duty stage ramps pick up on the same measurements so that installation is almost tool-free. In venues mixing brands, a universal adapter plate or adjustable foot compensates for minor dimensional mismatches.

Applications Beyond the Stage Edge

- Broadcast Facilities: Rolling cases brimming with AV equipment benefit from low-angle access.

- Education: School stages and university theatres value durability against frequent changeovers.

- Festivals: Outdoor stages encounter mud, rain, and high turnover, robust stage ramps stay dependable under those extremes.

- Corporate Events: Conference centres demand a clean look and rapid transition from plenary to breakout spaces.

- Government and Civic Buildings: Accessibility regulations require compliant pathways for public gatherings.

Maintenance Checklist

Routine examination extends service life and upholds safety standards:

- Torque-check all fasteners, especially hinge pins and deck clamps

- Inspect welds and extrusion corners for fatigue cracks

- Replace worn areas, rust spots, or chipped coatings promptly

- Confirm handrail integrity—loose uprights introduce a serious hazard

- Store ramps on padded supports to prevent twist or ding damage

Installation Workflow

- Survey the site: verify floor level, measure deck height, clear obstruction zones.

- Assemble in line with manufacturer sequence; start at the stage edge and work towards the floor.

- Lock modules using dedicated clamps or quick pins; apply torque settings where stated.

- Fit handrails, toe-boards, and any kick plates before the ramp enters service.

- Conduct a live roll test with flight-cases or weighted dollies to confirm stability.

Advantages at a Glance

- Minimises manual handling injuries by providing a controlled gradient

- Keeps show schedules on track through faster load-in and strike

- Demonstrates compliance during licensing inspections

- Projects a professional image: clean lines, matching finishes to stage platforms

Summary

Heavy-duty stage ramps form a critical connection between backstage operations and the performance area. By prioritising high load capacity, durable surface treatments, and precise integration with stage platforms, venues gain an asset that delivers reliable service through countless productions. A considered purchase, matched precisely to anticipated loads, available footprint, and legal obligations. sets the stage, quite literally, for safer, more efficient workflows.