Exhibition Stands, Truss Booths & Modular Exhibition Truss Systems

Trade shows place brands side-by-side, often in busy halls where first impressions arrive in seconds. A clearly structured display sets the tone, guiding visitors while showcasing products, graphics, and interactive areas. The information below gathers practical knowledge on exhibition stands, outlines ways a trade show truss booth can adapt to floor plans, and looks at how a modular exhibition truss system helps exhibitors refine layouts season after season.

Core Principles of a Truss Booth

Any truss booth follows a few straightforward principles: strength, repeat use, and visual clarity. Once the framework locks together, the structure handles banners, screens, or hanging features without drama. Many designers favour truss because the open framework accepts clamps and brackets, letting the same kit work at multiple venues with new graphics each time.

Main considerations include:

- Weight rating of the truss components and the load each joint can carry.

- Space for graphics, shelving, or digital screens without cluttering walkways.

- Time on site – a skeleton crew often has limited hours to build before doors open.

- Storage footprint when the system is packed away between events.

Stand Layout Categories

Exhibition organisers usually divide floor space into four key categories. Recognising the differences helps exhibitors pick the right truss exhibition stand configuration.

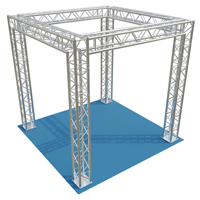

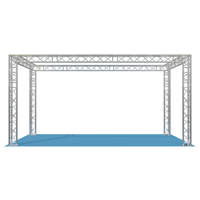

Inline

Placed shoulder-to-shoulder with neighbouring brands. A straight back wall plus side returns keeps assembly time low. Truss sections span the width, lifting graphics clear of floor-standing furniture.

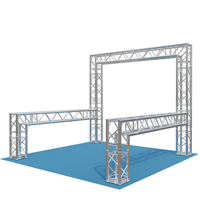

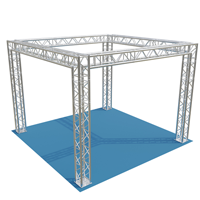

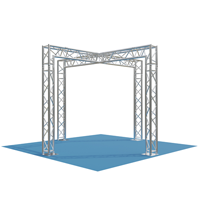

Corner

Open on two sides, often catching footfall from two aisles. A corner build suits product counters on one edge and a demo zone on the other. Truss uprights in each corner support overhead branding rails.

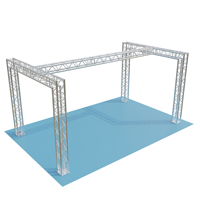

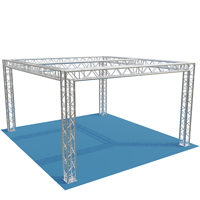

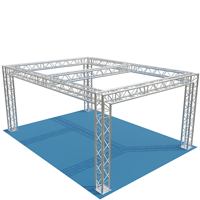

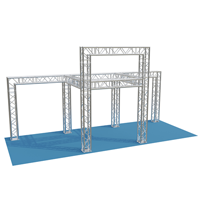

Peninsula

Open on three sides, giving broad sightlines. A short central wall anchors screens or shelving while the external frame carries large banners.

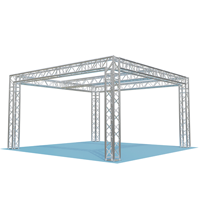

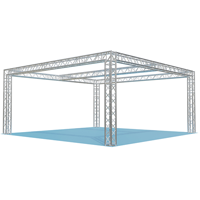

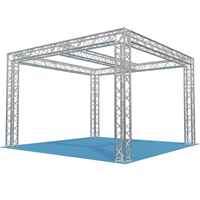

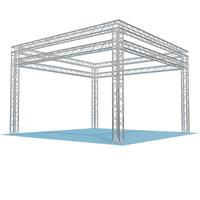

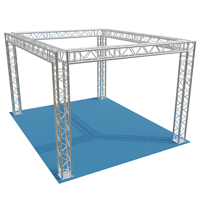

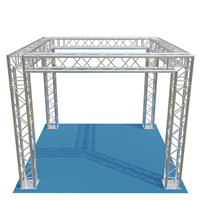

Island

Accessible from every direction, an island stand benefits from a four-post or six-post design. The overhead truss ring becomes a landmark, drawing attention from across the hall.

Reasons Exhibitors Choose an Exhibition Truss System

- Modular build: Straight lengths, corner cubes, and base plates combine in countless shapes. Future floor plans rarely match previous bookings, yet the same kit adapts with different connectors.

- Consistent finish: A single material across the framework prevents visual distractions and keeps brand artwork in focus.

- Accessory support: Spotlights, sound bars, screens, and shelves mount directly to the frame, avoiding extra tripods or separate towers.

- Mechanical reliability: Properly maintained joints lock tight show after show, reducing replacement costs.

Technical Features

Modern exhibition truss employs standardised connectors and tool-friendly fasteners. While details differ between manufacturers, the following points remain routine:

- Quick-fit couplers – pin and sleeve sets or bolted clamps secures sections in seconds.

- Cable management – channels in the chords hide signal and power runs, keeping aisles clear.

- Finish options – powder coat, clear anodise, or RAL colours match corporate palettes.

- Calculations – published load tables guide safe placement of screens or suspended features.

Graphic Integration

A display lives or dies on its visuals. Truss frames give design teams clear anchor points for:

- Rigid panels using hook-over brackets.

- Stretch fabric sleeves pulled smooth around the perimeter.

- Hanging banners fixed at high level for long-range branding.

- Interactive touch screens secured within protective cages.

Floor Space Planning

The best graphics fail if furniture blocks the view or crowds visitors. Early CAD drawings map:

- Walkways – minimum 1.2 m wide in heavy traffic areas.

- Gathering spots – demo zones need elbow room plus safe cable runs.

- Storage – cupboards hide cartons, giveaways, and personal items behind clean façades.

- Power – socket locations dictate rigging of extension rails in the frame.

Assembly Process

- Lay ground protection sheets to avoid scratching venue flooring.

- Arrange base plates according to the plan, checking clearance from aisles.

- Connect uprights and horizontal beams at ground level before raising sections.

- Insert diagonal braces where specified to stiffen long spans.

- Secure graphic rails, then lift complete walls using lifting aids or crew ladders.

- Finish with banner bars, lights, and screen brackets once the frame is square and level.

Maintenance Guidelines

Proper care guarantees repeat performance:

- Inspect locking pins and threaded inserts after every dismantle.

- Wipe surfaces with mild detergent and a soft cloth, avoiding abrasives.

- Store in padded sleeves or foam-lined trunks to protect joints.

- Keep a record of batch numbers in case replacement parts are needed later.

Sector Applications

While exhibition stands turn up in every market, certain industries lean heavily on the format:

- Consumer electronics – product launches demand high-level branding and clear viewing angles.

- Automotive – vehicles park beneath the truss canopy, benefiting from directional lighting.

- Education – universities highlight faculties on flexible displays that adapt between recruitment fairs.

- Food and drink – tasting counters nest inside corner frames, allowing rear storage of chilled stock.

- Interior design – large fabric prints recreate room sets within peninsula layouts.

Reusable Kit versus One-Off Builds

Permanent installs differ from roadshow gear. A modular exhibition truss system costs more up-front than timber flats but spreads that spend across multiple campaigns. The decision often rests on these points:

- Number of planned events within a two-year window.

- Availability of crew trained to handle truss components.

- Storage space between shows.

- Green objectives – re-use cuts waste and reduces logistical carbon impact.

Transport and Logistics

Each truss length slides into flight cases or pallet-sized tubs. Shorter sections travel in estate cars; longer spans ride on box vans. Colour-coded tags speed on-site identification, and QR labels link to digital part lists for quick checks.

Colour & Finish Trends

Natural metal tones once dominated, yet brands increasingly request:

- Matt black to focus attention on illuminated products.

- White for a clean, medical or tech-orientated look.

- Corporate colours that link the display directly to packaging or advertising campaigns.

Integrating Digital Content

Screens, projectors, and touchscreen kiosks slide into the structure, drawing power through concealed cables. When larger LED tiles enter the conversation, engineers calculate deflection and add piggy-back frames if required.

Stand Dismantle Strategy

A dismantle plan matters as much as setup. Busy break-downs risk lost parts or damaged graphics. Well-labelled tubs, checklists, and a designated parts runner speed the process, freeing crew before overtime charges kick in.

Customisation Options Beyond Graphics

Timber fascias, fabric canopies, or LED edge lights twist a standard frame into something distinctive. Velcro-ready panels clip straight onto the chords for quick message swaps between show days.

Insurance Considerations

Truss inherently carries a higher declared value than roll-up banners. Exhibitors often add temporary insurance for transit and build periods. Policies typically cover accidental damage, loss in transit, and third-party claims during erection or breakdown.

Summary

From compact inline displays to expansive island pavilions, the modular nature of a truss exhibition stand keeps pace with shifting objectives. Reliable joints, clear load data, and adaptable accessories combine to deliver consistent results across varied venues. The long service life of truss structures supports sustainability aims, while the freedom to refresh graphics each season maintains visual interest without a full rebuild.