Triangle Truss Structures – Design, Use & Practical Guidance

Triangle truss designs are everywhere: clustered above theatre stages, framing large format prints at exhibitions, or supporting sound arrays on outdoor gigs. Their three-chord layout produces a compact profile that manages load paths efficiently while remaining visually neat. By combining aluminium alloy with proven jointing methods, modern tri truss assemblies satisfy both practical and aesthetic demands across entertainment and display work.

Tri Truss: Why Three Chords?

A triangle distributes force through each side without relying on additional bracing. Translated into tubing, the shape limits bending under point or evenly spread loads, so a triangle truss system can often span respectable distances with less material than a comparable four-chord alternative. The result is less dead weight in the roof, lower pick-up loads for motors, and reduced truck space during transport.

Triangle Lighting Truss Material and Manufacture

Sections are generally produced from 6082-T6 aluminium alloy, a grade appreciated for its balance of mass and tensile strength. Main tubes may sit at 48-51mm outer diameter with 2–3mm wall thickness, depending on series. Bracing struts link the chords at calculated angles to curb lateral twist. For speedy on-site work, spigot joints remain popular; they slide into conical receivers and are secured with steel pins and R-clips. Bolted ends remain available when users prefer a fixed interface.

- Standard finish: mill-polished aluminium, easy to clean and resistant to corrosion.

- Alternative finishes: powder coating in RAL colours, or anodising for installations where the framework stays on show.

- Inspection: weld beads are TIG-formed, and every batch undergoes dimensional checks before dispatch.

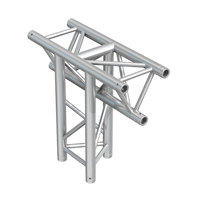

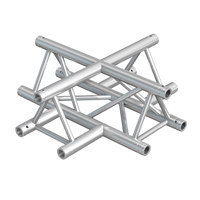

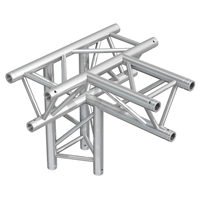

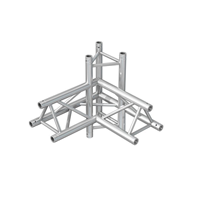

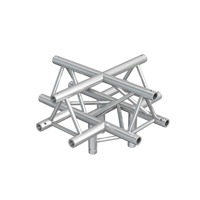

Module Options & Junction Pieces

Straight lengths tend to arrive in 0.25m increments up to 4m as off-the-shelf items. Shorter sections are handy for tight truck packs or for curves; longer pieces cut down the number of joints in large roofs. Corner blocks create two-way, three-way or four-way turns, while truss circles are built from pre-curved arc segments that lock together. The flexibility of the system means that a designer can draw fluid shapes without deviating from a single structural family.

Typical Loading Practice

Any aluminium triangle truss should be referenced against its manufacturer's loading table. Figures specify uniformly distributed load, centre-point load, and maximum span. In day-to-day use, the notes below help riggers keep within safe working limits:

- Confirm the exact span before choosing the chord size; overstretching a lightweight series invites deflection.

- Keep spot loads close to nodes; mid-bay hanging amplifies bending moments.

- Lock couplers square to the tubes so clamps transfer shear properly.

- Document every fixture weight in the rig plan, including cabling.

Project Environments Where Triangle Truss Excels

The following installations illustrate why many crews favour triangle stage truss over other profiles:

- Club Lighting Grids. The slim outline is less intrusive above the dancefloor, yet it carries moving heads and strobes comfortably.

- Temporary Stage Roofs. Fewer cords cut wind exposure and make sheeting easier to tension.

- Retail Displays. Clean lines form geometric backdrops for banners or LED panels without overshadowing the products.

- Broadcast Studios. A triangle lighting truss allows cable runs inside the chords while keeping sightlines clear for cameras.

- Architectural Features. Circular or sweeping curved sections lend a technical accent to foyers and atriums.

Accessory Integration

A broad catalogue of drop arms, mounting plates and ladder extensions bolts directly to the chords. Collectively these parts increase creative scope without forcing a change in basic structure. For example, a line-array adapter slides onto the bottom chord to accept standard 35mm poles, whereas quick-release half couplers join LED screens in seconds.

Assembly Steps in Brief

While every model carries its own instruction sheet, the routine below covers most onsite builds:

- Lay sections on protective mats and align ends.

- Insert spigots, ensuring holes match.

- Tap spring pins into place; retain with safety clips.

- Raise spans with manual stands or chain hoists, observing local safe working practices.

- Torque any bolted joints to the figure in the technical file.

- Attach fixtures only after the structure is fully braced and certified.

Aluminium Triangle Truss Maintenance and Inspection

Regular checks prolong the service life of any tri truss stock. Surface scuffs are cosmetic, yet dents deeper than the tube wall call for removal from load-bearing duty. Weld zones deserve special attention; look for hairline cracks or discolouration. Moving pins should seat snugly, and spigots must not wobble. After wet outdoor shows, dry the pieces before return to flight cases to prevent galvanic marking.

Choosing the Correct Triangle Truss System

Selection hinges on three variables: span, load, and visual goal. Short throws with modest lighting often succeed with compact 29cm chord centres, keeping ceiling height intact. Long-throw FOH trusses in arenas may step up to 40cm or more, accepting higher rig weight and monitor clusters. Where form drives the brief, slimline dimensions coated in dark finishes help the framework blend with set elements.

- Span under 6m: consider light-duty series for weight savings.

- Span 6m to 12m: mid-range cords, often 35-40cm centres.

- Beyond 12m: engage an engineer and select heavy-duty series with braced joints.

Logistics and Supply of Triangle Stage Truss

Bulk stock sitting at our UK warehouse reduces lead times. Custom powder-coated runs or pre-curved arcs demand longer schedules, so early ordering avoids bottlenecks. Palletised delivery prevents scratching; shorter elements pack into trunks for courier shipment. Project managers frequently mix hired spans with new purchase, maintaining budget flexibility while ensuring critical pieces remain pristine.

Triangle Truss System Summary

From compact club rigs to expansive festival roofs, triangle truss continues to answer structural questions with a simple three-chord solution. Its balance of weight, capacity and appearance keeps the format relevant across staging, exhibition, and architectural applications. Correct specification, sympathetic handling and routine inspection ensure safe, reliable service year after year.