Staging Accessories

A performance area stands or falls on the small components that hold it together. Bolts, clamps, skirts, and handling aids rarely catch the spotlight, yet they decide how quickly a crew can work and how confident performers feel. This page brings together a technical look at staging accessories, highlighting the practical choices trusted for a theatre's performance stage, touring productions, civic halls, and stages for education facilities across the country.

Safety Features Worth More Than Their Weight

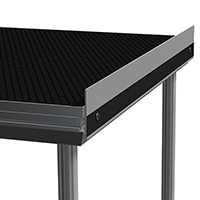

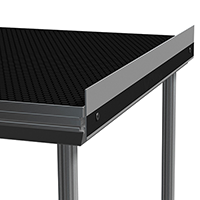

Guarding the edge of a raised surface might appear obvious, still it remains the most‐missed item on many kit lists. A solid rail system fitted with quick-lock posts eliminates wobble, satisfies inspectors, and reassures crew moving heavy gear. Equally important, corner bumpers soften sharp joins, while anti-slip edging protects both equipment and flooring. When budgets allow only a handful of upgrades, these are usually chosen first.

- Rapid-fit rails that lock without tools

- Non-marking rubber pads that grip polished floors

- Integrated latch pins preventing deck creep during energetic shows

Hidden Connectors Doing Heavy Lifting

Connection hardware sits out of sight, yet its engineering tolerances are critical. Choosing parts that match deck thickness and extrusion design saves hours of frustration on-site. Common styles include:

- Internal couplers – slide into aluminium profiles and draw deck edges together

- External brackets – straddle adjoining frames, ideal where under-deck clearance is limited

- Multi-angle plates – permit hexagonal or staggered layouts often required for orchestra pits or catwalk runs

Moving, Storing, and Protecting Components

Touring productions, college drama departments, and town-hall caretakers share one problem: everything has to fit back into a cupboard, truck, or flight case. Wheeled dollies sized to match deck width prevent edge damage and speed up changeovers between events. For smaller items, stackable crates keep pins and clamps grouped by size, avoiding the classic five-to-midnight scramble when a single fastener goes missing.

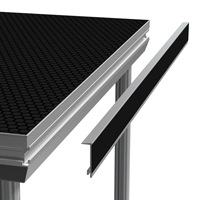

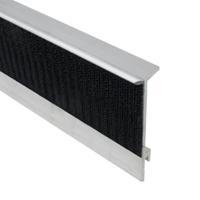

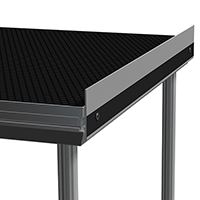

Clean Lines and Professional Finish

An audience seldom notices the under-frame of a raised floor, yet exposed metalwork tends to dominate in photographs and recorded footage. Simple fabric skirts fitted with hook-and-loop tapes hide structural elements, cables, and spare mic stands. Fire-retardant cloth remains the standard in public venues, while vinyl kick-panels serve well outdoors where mud or standing water is expected.

Material Choices and Long-Term Value

Stainless steel fixings resist coastal air. Zinc-plated mild steel offers a cost-effective option indoors. High-impact polymers reduce weight where crews load vans by hand. The right blend depends on frequency of use, storage conditions, and expected loading. Regular inspection: checking for thread wear, bent plates, or chipped coatings, prolongs service life and keeps insurance assessors happy.

Putting a Kit List Together

Rather than beginning with aesthetics, seasoned technicians tend to:

- Confirm deck manufacturer and profile code

- Note maximum live load and any height extensions planned

- Mark entry and exit points for crew traffic

- Allocate budget for handling carts, often forgotten until the truck door closes

- Add skirts and trim last; appearance gains more from straight seams than exotic fabrics

Balancing Initial Outlay with Operational Savings

A reinforced trolley costs more than a makeshift pallet and strap, yet pays for itself the first time a deck corner avoids impact damage. Likewise, stainless fasteners hold resale value long after mild-steel parts show surface rust. Skirts protect cable runs from curious fingers, cutting call-out charges for damaged leads. Hidden savings mount up quietly over several seasons.

Light Maintenance, Heavy Pay-off

A monthly regime: tightening couplers, wiping threads, washing fabric at low heat, extends usable life far beyond warranty periods. Crews often log checks on simple spreadsheets or QR-coded sheets taped to flight cases, creating a record valued by venue managers and insurers alike.

Planning Today for Tomorrow's Stage Size

Event briefs evolve; one week calls for a lecture rostrum, the next a three-tier band layout. Universal connector patterns and extension leg collars accommodate shifts in height or footprint without a new purchase order every time the spec sheet changes.

Key Takeaways

- Staging accessories ensure structural integrity, visual polish, and straightforward logistics.

- Compatibility checks prevent delays on build day.

- Investment in quality materials lowers repair and replacement costs.

- Regular maintenance creates a safety record appreciated by insurers and licensing authorities.