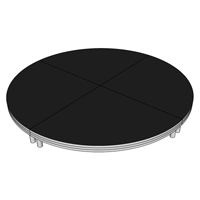

Camera Riser

Stability remains the unsung cornerstone of effective filming and still-image capture. A well-built camera riser delivers that stability by lifting camera bodies and their operators clear of obstructions, maintaining a consistent and level working surface, and guarding against the shake or flex that ruins critical footage. Stage Concepts curates a concise, purpose-driven selection of lightweight stage platforms aimed at broadcasters, production houses, and photographers who insist on dependable results session after session.

The Practical Role of a Camera Platform

Crowded venues, uneven ground, or simply the need for an improved sightline frequently demand an elevated perch. A camera platform answers that demand in a compact footprint. Rather than relying on makeshift stacks of cases or improvised furniture, crews gain a rigid, engineered support that withstands repeated use without sagging or twisting. This advantage is particularly valuable where a tripod alone cannot reach sufficient eye-level or where multiple operators share one vantage point.

Key Benefits at a Glance

- Consistent, level surface free from vibration

- Predetermined working height for predictable framing

- Anti-slip deck materials that keep feet and equipment anchored

- Construction rated for professional payloads, including operator weight

- Compact storage profile when disassembled

Variations: Photo Riser, Video Camera Platform, and Beyond

Not every assignment looks the same, so neither should every riser. A compact photo riser may suit a portrait studio wanting just enough lift to alter perspective. Larger photography risers come forward when two or three people, monitors, and cable looms share the same surface. Meanwhile, outside-broadcast crews often lean on a heavier video camera platform, confident it will support tracking heads, batteries, and shielding for adverse weather. Each format is built with overlapping goals: stable support and operator safety, but with subtle differences in deck size, leg architecture, and overall working height.

Core Camera Riser Construction Features

Materials matter. Aluminium alloys keep overall mass down yet resist corrosion. Steel bracing in high-load zones ensures the deck remains rigid even when operators step off-centre. Most professional solutions combine these metals, pairing lightweight frames with reinforced corners and cross-members. Deck boards arrive finished in textured, non-reflective coatings that reduce glare in bright rigs and provide valuable grip under footwear.

Load Handling

Each model carries a published safe working limit. Figures usually factor in a healthy safety margin to account for sudden movements, heavier lenses, or a second operator leaning in. Always verify that limit against total combined mass: camera body, support rig, head, and the person operating, before committing to a purchase.

Footprint and Height

Common footprints range from narrow, single-operator decks to broad units closer to small stages in width. Height is fixed at manufacture to guarantee rigidity, though bespoke dimensions can be produced for venues with unusual sightline requirements. When specifying a system, project managers often start with three numbers: desired elevation, available floor area, and anticipated user weight. Those figures inform nearly every other choice.

When a Dedicated Photography Risers Outperforms Improvised Solutions

It may seem quicker to place a tripod on a stack of crates, yet that approach introduces vibration, inconsistent heights, and, most importantly, risk. Purpose-built risers earn their keep through:

- Predictable set-up time; no last-minute searches for extra boxes or gaffer tape

- Uniform weight distribution across engineered beams, reducing chance of collapse

- Smooth deck edges that preserve cables and prevent snags

- Compliance with venue health-and-safety checks, satisfying insurers and site managers

Video Camera Platform Applications

A camera riser is as likely to appear in a theatre's back row as it is in a sports arena gantry. Typical scenarios include:

- Live music filming where the front-of-house position demands an over-crowd angle

- Conferences and keynote addresses requiring a clear shot of the lectern

- Film sets demanding low-footprint elevation inside tight rooms

- Studio photography sessions that benefit from slight elevation for group compositions

- Sports coverage seeking an unobstructed view across advertising hoardings

Camera Platform Safety Protocols and Best Practice

Professional environments impose strict checks on any load-bearing structure. Crews therefore confirm the following before first use:

- Leg locks engage fully and cannot release under vibration

- Deck panels sit flush with no raised corners

- Surface grip remains effective even when wet

Periodic inspection prevents minor wear morphing into outright failure. Loose bolts are tightened, deck coatings are cleaned, and any warped components replaced rather than patched. This schedule forms part of broader asset management, usually documented for insurance purposes.

Handling and Transport

Crews value swift turnaround between venues. For that reason, modern platforms arrive as modular parts featuring:

- Leg frames that nest together to minimise transport volume

- Deck panels light enough for one or two technicians to carry safely

- Simple pin or cam locks instead of separate fasteners that can roll away

- Optional padded bags or flight cases guarding deck surfaces against scratches

Load-out often mirrors set-up in reverse: unlock, slide panels free, stack, and wheel to the truck. Because each element weighs less than typical lighting fixtures or speaker cabinets, the camera department rarely needs extra crew solely for the platform.

Extending Functionality

While a riser may ship as a basic flat deck, accessories can refine workflow. Rail kits protect operators leaning forward with long lenses. Cable hooks prevent tripping hazards. Weather hoods keep rain off electronics during outdoor shoots. Even small extras such as levelling feet make a measurable difference on sloping ground.

Some broadcast teams commission bespoke logo plates or colour-coded edging to align with the rest of their equipment fleet. Such customisation is less about branding than rapid identification—handy when multiple departments share one storage facility.

Specifying the Correct Product

Procurement normally begins with a simple checklist:

- Deck size required for personnel and kit

- Fixed working height that clears known obstacles

- Maximum combined load including operator

- Environmental considerations—indoor, outdoor, or both

- Frequency of transport and storage space in vehicles

Armed with those figures, technical managers match catalogue data against real-world demands. When unique site constraints arise, Stage Concepts supplies drawings and manufacture timelines for non-standard options.

Maintenance Schedule

Routine tasks extend service life significantly:

- Wipe deck surfaces after dusty outdoor shoots

- Store in a dry, temperature-stable environment

- Inspect welds and fasteners every three months

- Test anti-slip finish annually, renewing coatings where wear appears

A minor upfront commitment to cleaning and inspection prevents downtime later, particularly during back-to-back events where replacement stock is unavailable at short notice.

Conclusion

A dedicated camera riser offers far more than a simple lift in height. It introduces predictability, protects equipment, and streamlines workflows in spaces where clear sightlines are non-negotiable. Choosing the correct model brings lasting value across countless shoots, whether the task is a fast-moving broadcast or a deliberate studio portrait session. Built on robust engineering and practical features, these platforms continue to prove their worth whenever uncompromising stability is demanded.