Trussing and Trussing Structure for Event Professionals

In theatres, concert halls, broadcast studios and temporary outdoor venues, a safe method of supporting equipment remains essential. Trussing, a lattice of straight members joined at nodes, fulfils that role. When planned correctly, a trussing structure allows lighting bars, speaker clusters, screens or scenic elements to be positioned where required without overstressing the host building or relying on improvised fixings. The information below outlines core engineering principles, material choices, planning steps and maintenance routines commonly followed across the UK events sector.

Fundamental Engineering Concepts

A typical trussing span behaves as a series of triangular forms. Triangulation locks each chord in position, so compression and tension forces transfer through the entire frame rather than concentrating at a single point. The outcome is a relatively lightweight component capable of carrying loads that would overwhelm solid beams of comparable mass.

- Chords: The main longitudinal tubes that resist bending.

- Web members: Diagonals linking the chords, handling shear forces and stabilising the shape.

- Nodes: Intersections where chords and webs meet. Joints must stay rigid to maintain the original geometry under load.

Designers calculate stress levels using static analysis and, on complex assemblies, finite-element software. Safe working values then appear on published loading charts. Where dynamic forces (moving scenery, winched loads, or audience movement) may arise, additional safety factors enter the calculation.

Materials in Common Use

Most modern trussing employs an extruded alloy because of the favourable strength-to-weight ratio and corrosion resistance. Although lighter than steels of similar capacity, the alloy sections still provide the wall thickness required for robust connection points and repeated handling. Protective finishes vary. Anodising offers a clean, hard surface, while paint coatings serve either aesthetic or weather-resistant purposes.

Key Performance Considerations

- Tensile strength: Determines how much direct pulling force a chord withstands.

- Yield strength: The point at which permanent deformation begins. Higher values extend service life under repeated loading.

- Modulus of elasticity: Governs deflection over a given span. Low deflection remains vital where precision aiming of fixtures is required.

Connection Methods

Fast, reliable joints speed up assembly on site and keep alignment accurate. Conical couplers with tapered pins remain widespread, though threaded bolts and pre-installed quick-connect fittings also appear. Choice depends on technician preference, available tooling and project budget. Whatever the mechanism, the mating faces must be free from burrs, dirt and distortion. Even slight damage reduces bearing area, raising stress levels around the joint.

Configuring a Trussing Structure

Assessing the Brief

Every installation begins with a load list. Fixture weight, point spacing, cable routing and potential access paths all feed into an initial sketch. At this early stage, additional information covering wind exposure, roof height, floor loading and fire egress should be gathered. Omitting such data can jeopardise the entire schedule once on-site.

Selecting Span Length and Depth

Long spans reduce the number of ground supports but raise bending moments. A deeper profile counters that bending. Conversely, tight ceiling voids push designers toward shallower profiles, often at the expense of maximum span length. The final decision balances clearance, weight and aesthetics.

Calculating Point Loads and Reactions

After placing fixtures along the span, loading software or manual equations deliver the reaction forces at support points. These reactions inform the specification of hoists, stands or structural anchors. In multi-level grids, each lower chord not only carries direct equipment loads but also reacts to imposed forces from the framework above.

Typical Applications

Although best known for suspending lighting or audio, a trussing structure adapts to multiple scenarios:

- Creating a ceiling grid above an exhibition floor for banners and graphic panels.

- Supporting projection surfaces where conventional wall fixing points are unavailable.

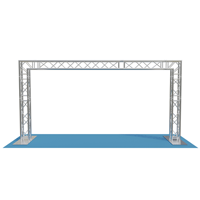

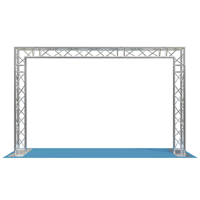

- Forming gateways or walk-through portals at outdoor events.

- Acting as ballast-free ballast holders when combined with outriggers and weights.

- Providing camera rails or track mountings in broadcast studios.

By varying bay length, orientation and bracing, the same stock sections handle either delicate scenic pieces or substantial electro-acoustic arrays. That flexibility justifies the component investment for hire companies and venues operating diverse show calendars.

Summary

Properly designed, installed and maintained trussing provides a stable, modular platform for creative ideas in entertainment, broadcast and corporate presentation. The engineering principles are straightforward, yet the consequences of error remain significant. Selecting sections with adequate capacity, reading the associated charts with care and engaging qualified riggers secures the desired outcome: reliable support with minimal fuss.