Single Stage Risers

Single stage risers provide a simple answer when performers, speakers or equipment need to sit just above floor level. The concept is straightforward: a rigid deck, a stable support frame and a surface capable of handling regular set-ups. Because the units remain compact and fairly light, transport crews seldom need specialist vehicles or lifting gear. At the same time, overall safety margins stay high, even when the riser must carry instruments, several people or specialist AV hardware.

Over recent years, the demand for nimble solutions has grown in music education, touring productions and civic facilities. This has seen the humble stage riser platform move from a bulky wooden block to a refined item built from modern composites, smart fixation methods and slip-resistant finishes. The sections that follow outline how these changes translate into practical benefits on-site.

Why a Single Platform Instead of a Full Stage?

A single deck sits midway between an improvised crate and a complete stage system. That middle ground proves useful for:

- Rooms where a full modular build would dominate floor space.

- Events with short change-over times that cannot accommodate lengthy construction.

- Groups returning to the same venue and seeking repeatable results with minimal fuss.

The reduced footprint trims transport costs, speeds up load-in and shortens risk assessments. For organisations with limited storage space, one compact portable riser platform makes far more sense than several large sections.

Main Advantages at a Glance

- Portability: Most contemporary designs stay under airline baggage weight limits, allowing travel in standard vans or even estate cars.

- Rigid construction: Welded or bolted frames resist torsion, ensuring the deck does not flex under dynamic load.

- Quick assembly: Locking legs or fold-out braces click into position within minutes; often no tools are required.

- Non-slip top surface: A textured laminate keeps feet, instrument cases and stage monitors firmly in place.

- Space saving: Stackable legs or nesting frames halve the volume needed in storage cages and store rooms.

Combining these properties keeps stage risers relevant in situations where traditional plywood rostra would prove too heavy or too awkward to position.

Regular Applications

Despite modest dimensions, a single small stage riser opens the door to many layouts. Venues often allocate one or two units for:

- Music practice rooms: For large classes and band stage practices, it helps to raise the tutor above the students, particularly helpful for instruments where the tutor is required to sit down (for teaching the drum kit, for example).

- Public meetings: Raise a keynote speaker above seated audiences for improved sightlines with conference staging riders.

- Photography sessions: Form a clear, level base for group portraits without resorting to step ladders.

- Choir rehearsals: Separate sections of the ensemble by height, helping sound projection.

- Trade demonstrations: Present machinery or prototype items safely at waist height during product launches.

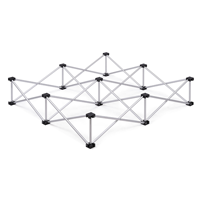

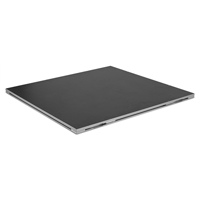

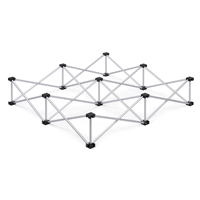

Materials and Build Details

No single recipe suits every brief, yet several design principles remain consistent across reputable portable risers:

- Deck core: Engineered timber or lightweight composite panels deliver stiffness without excessive mass.

- Frame: Tubular steel or alloy extrusions supply strength at edges where impact is most likely.

- Finish: Powder-coat or hard-anodised layers guard against knocks, humidity and routine cleaning chemicals.

- Fasteners: Flush fittings stop clothing snags while internal fixings allow quick swap-out during servicing.

- Protective standoffs: Rubber or nylon feet prevent noise transmission into wooden floors and protect polished surfaces.

Manufacturers pay close attention to load paths, ensuring weight transfers through vertical supports rather than deck skins. This philosophy produces long service life and predictable deflection figures even after hundreds of assemblies.

Selection Checklist

When shortlisting a stage riser platform, technicians often start with three simple figures:

- Intended load: Musicians plus backline can exceed 300kg; speakers working alone rarely top 100kg.

- Deck height: Common rise options sit between 200 mm and 600 mm. Going higher may call for handrails under local regulations.

- Footprint: Match the deck size to available space plus a safe perimeter; never block fire routes or cable runs.

Set-up, Transport and Upkeep

Correct handling has a direct effect on life expectancy. A short routine serves well in fast-moving venues:

- Unfold legs fully and listen for positive locking clicks before placing any load.

- Place the unit on a flat surface, shim only if essential, and avoid stacking casual items beneath.

- After use, wipe down with a mild detergent, especially if drinks, rosin or tape have marked the deck.

- Store flat or return to a dedicated truck pack frame to prevent warping.

- Log serial numbers and inspection dates so defects can be traced swiftly.

Such disciplines mean fewer surprises during the next event and keep insurance inspectors happy.

Optional Accessories

A single riser may function without extras, yet several add-ons refine day-to-day use:

- Clip-on guardrails for venues that set strict edge-protection rules.

- Lightweight steps for frequent access by children or presenters carrying instruments.

- Skirts to tidy cable runs and create a clean visual line across multiple band risers.