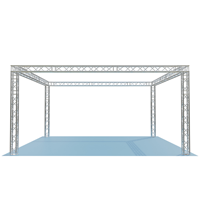

Lighting Truss

A well-planned lighting structure lies at the heart of every modern stage, club, or exhibition. Engineered frameworks carry fixtures overhead, maintain sightlines, and keep cables orderly. Lighting truss performs all three tasks while remaining modular and repeatable, saving crews time whenever the layout changes.

Defining Light Trussing

Light trussing refers to prefabricated beams assembled into grids, arches, or towers for fixture support. Produced from high-strength metals, each length is drilled, braced, and certified for predictable loading. Unlike single tubes, the triangulated design spreads weight evenly, allowing greater spans with modest unit weight.

Lightweight Lighting Truss in Practice

Tour schedules and fast turnovers demand gear that can be lifted, packed, and driven without excessive manpower. A lightweight lighting truss answers that need by delivering structural integrity at a reduced mass. Less material means:

- Compact truck loads and lower haulage costs

- Shorter build and strike periods on multi-date tours

- Minimal manual handling strain for small crews

- Compatibility with hand-operated lifts and winches

Despite the slim profile, every beam is rated individually. Load charts indicate maximum centre-point and distributed capacities, allowing design teams to balance fixture counts against safe working limits.

Where Lighting Trussing Appears

Event technology departments rely on truss across a broad spectrum of projects. Common deployments include:

- Ceiling grids in theatres and rehearsal studios

- Mobile concert wings for medium-scale festivals

- Hotel ballrooms hosting conferences or award evenings

- Churches and educational halls upgrading legacy lighting

- Pop-up brand activations requiring a temporary rig

In each environment, predictable hardware simplifies repeat set-ups and assists with compliance inspections.

Lighting Rig Truss Concepts

Rigging teams rarely install identical formats twice. One night calls for a straightforward straight run; the next may involve multi-level boxes or curved arrays. Lighting rig truss allows this freedom because pins, connectors, and corner pieces share a common interface. Designers can:

- Extend an existing run without replacing the whole frame

- Introduce angled sections to follow stage contours

- Hang scenic elements alongside luminaires

- Swap heavy discharge heads for lighter LED fixtures without major rebuilds

Each alteration remains reversible, preserving the inventory for future programmes.

Lighting Truss Ceiling Mount Methods

Venues with restricted floor plans often secure lengths directly overhead. A lighting truss ceiling mount system can attach to primary building steel, concrete anchors, or secondary grids, depending on load paths. Advantages include:

- Clear walkways and unobstructed stage access

- Permanent cable infrastructure, reducing set-up time

- Improved safety by removing trip hazards

- Lower visual impact, keeping the audience focus on performance

Appropriate fixings, such as drop-forged eyebolts, clamps, and load-rated chain, must be specified in consultation with structural engineers.

Key Points When Selecting Lighting Truss

Several factors govern specification:

- Span Length- Longer distances between supports increase bending forces and may demand thicker chords or extra bracing.

- Suspension Method- Ground-supported towers differ from flown grids; each route has unique stability checks.

- Fixture Density- LED pars weigh little, while hybrid moving lights can exceed 30kg. Load balance across the run remains critical.

- Transport Footprint- Folding or shorter segments ease logistics for touring personnel.

- Future Expansion- Choosing a widely adopted profile secures spare parts and simplifies cross-rental.

Maintenance Procedures

Routine checks protect both equipment and staff. Visual inspections before every lift look for dents, cracked welds, or damaged fasteners. Detailed examinations on an annual cycle may include:

- Magnetic particle testing of suspect joints

- Gauge measurements to verify chord straightness

- Torque assessments on critical bolts and pins

- Documentation updates for insurance or council oversight

Any section failing inspection should be removed from service until rectified or replaced.

Who Relies on Lighting Truss?

Beyond the headline touring sector, many smaller operations have embraced modular truss. Community arts centres benefit from shared hire stocks, while corporate communication agencies prefer discreet ceiling systems for televised streams. Even rental houses use standardised parts to serve varied briefs without inflating inventory.

Outdoor Considerations

Weather exposure introduces new variables. Galvanised finishes, drainage holes, and wind bracing protect temporary structures on open ground. Load calculations adjust for lateral forces, while non-slip paint markers guide riggers during wet assembly.

Summary

Lighting truss, particularly in lightweight formats, remains an indispensable tool for stagecraft and architectural illumination. Its adaptability, repeat-use efficiency, and codified safety standards make it the preferred method for suspending modern show technology.