Stage Truss

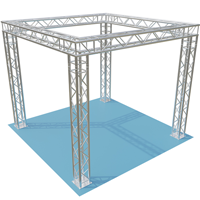

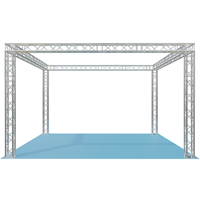

Modern live production relies on a stable framework overhead and around the performance space. That framework is the stage truss: a modular assembly designed to carry lighting, sound, video, scenery, and signage without distracting from the show itself. A stage truss system combines many short sections into longer spans, bends, or arches, giving designers room to sculpt layouts that match the venue and the brief. Touring providers favour quick-connect fittings; fixed-install venues value clean lines and durable finishes. Either way, stage trussing underpins the technical craft behind concerts, theatre, broadcast, and corporate events.

Construction Principles

Each piece of stage truss is built from longitudinal chords linked by diagonal bracing. The geometry spreads load forces so that lighting fixtures and loudspeakers can be mounted without unacceptable deflection. Connection ends vary - spigot and pin, half-conical, or bolted plate - but the purpose is identical: rapid, repeatable alignment that keeps structural integrity intact after countless assemblies.

Why Aluminium Stage Truss Takes the Lead

Aluminium stage truss dominates the market for clear reasons:

- High strength when compared with its mass, easing transport and manual handling.

- Natural resistance to corrosion, important for tours that move between damp festivals and indoor arenas.

- Ease of machining, welding, and surface finishing, which expands the range of accessories that can be attached.

- Predictable mechanical properties, allowing engineers to publish accurate load tables for safe practice.

Core Characteristics of a Stage Truss System

- Modularity - straight lengths, corner blocks, base plates, and sleeve adaptors combine to suit almost any rig size.

- Load Capacity - calculated ratings guide how much equipment can be hung and where. Even distribution is vital.

- Compatibility - consistent end fittings make it possible to add new lengths to an existing stage truss system years after the first purchase.

- Finish Options - natural mill finish remains popular, though black powder-coat is often specified for theatre and broadcast where reflections must be reduced.

- Service Life - regular inspection of welds, pins, and cords allows aluminium sections to remain in circulation for many seasons.

Where Stage Trussing Earns Its Keep

Although the first thought is usually a rock show, stage truss turns up almost everywhere:

- Festival main stages, providing long downstage spans for front-lighting arrays.

- Theatre grid replacements in buildings without traditional fly towers.

- Broadcast studios needing flexible points for cameras, microphones, and scenery elements.

- Conference ballrooms, where discreet black truss frames projectors and compact line arrays.

- Community halls that host touring drama one week and an awards ceremony the next.

Stage Lighting Truss

Lighting design rests on angles, height, and safe rigging positions. A dedicated stage lighting truss gives directors the freedom to place fixtures exactly where throw distance and field width demand. Moving lights, strobes, profile spots, and pixel battens can be arranged in layers: front-wash across the apron, key light upstage, effects truss above. The system keeps cables neat, the beam paths clear, and the sight-lines uncluttered.

Who Depends on Stage Trusses?

The list stretches well beyond headline tours. Typical users include rental houses, civic theatres, production managers for sporting ceremonies, hospitality groups running seasonal shows, places of worship with expanding audio-visual demands, and academic institutions training future crews. Each sector values the same qualities: portability, load capacity, and predictable engineering data.

Truss for Stage Summary

From a compact school performance to a stadium-scale spectacular, a stage truss system provides the skeleton that makes modern live production possible. Its modular nature shortens build times, aluminium construction keeps weight down, and published load figures underpin event safety. Attention to planning, inspection, and correct rigging hardware turns those advantages into reliable daily practice. In short, stage trussing remains central to creative freedom and technical assurance across the entertainment world.