Stage Decks

Single stage decks sit at the heart of almost every live performance space. A single panel may look unremarkable on its own, yet once linked with its neighbours it becomes the trusted terrain that actors, musicians, and technicians rely on day after day. Reliability matters far more than flair here; every screw, brace, and surface layer is expected to take punishment without complaint.

Why These Panels Matter

A stage may shift between drama, dance, and amplified concerts within a single week. Constant change places exceptional demands on the supporting surface. Modern stage decking answers that challenge through engineered cores, rigid frames, and finishes chosen for grip as well as appearance. When specified correctly a deck allows crews to reposition scenery swiftly, performers to move with confidence, and load-in teams to keep schedules on track.

Key Stage Decking Build Elements

- Core Board: High-density plywood or composite layers pressed under uniform pressure create a panel that resists warping.

- Perimeter Frame: Steel or engineered timber profiles enclose the core, protect edges from impact, and distribute weight.

- Top Surface Choices: Hardwearing phenolic laminate, painted birch, or a textured coating for a dedicated non-slip stage deck.

- Connection Points: Pre-installed corners or side channels accept clamps, ensuring panels lock firmly and cannot creep once loaded.

- Underside Bracing: Cross ribs minimise deflection across wider spans and preserve a solid feel underfoot.

Performance Standards for Pro Staging

Panels classed for pro staging do far more than survive static weight. They must shrug off vibration from bass amplifiers, resist indentation from flight-case wheels, and remain quiet when performers land from a jump. Typical specifications include:

- Uniform distributed load ratings commonly exceeding 500 kg per square metre.

- Dynamic point-load capacity suitable for drum riser positions and rolling scenery.

- Surface coatings tested for slip resistance even when stage fog or minor spills are present.

By meeting these thresholds, a venue gains assurance that staging issues will not halt a show in full flow.

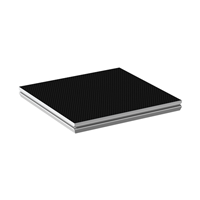

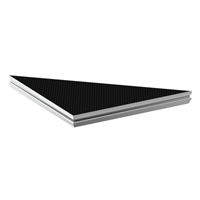

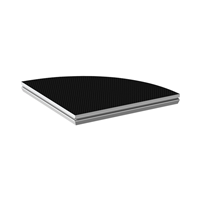

Stage Deck Platform Panel Sizes and Shapes

Despite the term "single", a panel can arrive in many footprints. Standard rectangles remain the most popular because they tile together cleanly, yet squares, triangles, and corner pieces appear regularly in stock catalogues. Bespoke dimensions are also possible, though longer lead times are normal. Matching thickness and edge profile across every size helps the resulting stage deck platform feel monolithic once built, even if the plan includes angles or height changes.

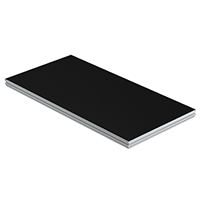

Finish Options Explained

Finish choice influences both safety and aesthetics:

- Smooth Paint: An economical coating, easy to repaint for set designers needing colour changes, though less forgiving when moisture is present.

- Phenolic Birch: Dark brown film over birch ply leaves a clean, semi-gloss appearance and offers respectable grip.

- High-Grip Texture: The go-to for dance troupes and rock venues - this is the classic non-slip stage deck surface.

Whichever route a venue chooses, a consistent finish across the entire platform avoids distracting seams under stage lighting.

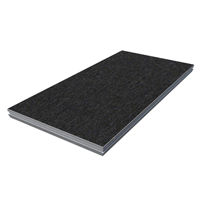

Compact Stage Deck Choices

Storage rooms are often smaller than planners would like. A compact stage deck weighs less and slots into tighter spaces, easing manual handling at the same time. Thinner cores, aluminium hybrid frames, or shorter lengths keep mass under control without sacrificing load rating. Schools, corporate conference suites, and touring merch stages draw particular benefit from this lighter format.

Connection and Alignment Systems

Speed counts during a turnover between acts. Repeated handling has driven manufacturers toward simple, tool-lite locking systems. Common approaches include:

- Top-mounted knobs: A quarter turn draws adjoining panels together.

- Underslung cam clamps: Invisible from above, favoured where a clean look is paramount.

- Side channel bars: Slide in, tap home, done. Popular with hire companies thanks to their abuse tolerance.

Primary Applications

Single panels support settings far beyond the traditional proscenium arch:

- Theatre extensions into forestage pits.

- Festival front-of-house mix positions requiring solid footing for consoles.

- Chamber orchestras assembling temporary risers in heritage sites.

- Film production crews creating level work decks inside sound stages.

- Corporate presentations where branding overlays must sit flush and stable.

The adaptability of individual stage decks allows designers to rearrange floorplans without replacement purchases.

Structural Verification

Certificated load data offers measurable peace of mind. Panels leave the factory with stamped ratings derived from lab tests that replicate worst-case conditions. Documents typically cover:

- Deflection at maximum distributed load.

- Shear resistance at joint lines.

- Point load resilience, simulating concentrated weight from feet or wheels.

Compliance with relevant British and European standards keeps insurers, local authorities, and touring production managers satisfied.

Maintenance Routine

Routine care is refreshingly undramatic:

- Visually scan edges after each strike for delamination or dents.

- Check clamps or fasteners for stripped threads and replace promptly.

- Clean surfaces with mild, non-abrasive solutions; harsh chemicals may degrade textured coatings.

- Store panels flat and off a damp floor, encouraging airflow to every face.

A modest toolkit and disciplined inspection schedule will see panels run reliably for many seasons.

Selection Checklist

Before issuing a purchase order, technical managers usually run through a short list:

- Weight per panel — does local manual handling guidance permit two-person lifting?

- Finish texture — will the programme include tap dance, or mainly spoken word?

- Locking style — does it match the existing stock, or is an adapter plate required?

- Height interface — is the chosen under-structure compatible with frame recesses?

- Storage — can the building accept full-size panels, or is a stacked trolley route essential?

Non-Slip Stage Deck Long-Term Value

Initial outlay on quality stage deck platform panels may appear higher than budget options, yet the arithmetic changes once repair costs and downtime enter the equation. A cracked surface mid-tour means immediate replacement and shipping delays. In contrast, pro-grade units weather transport knocks and constant flooring changes without drama, paying for themselves through longevity alone.

Environmental Considerations

Sustainability is no longer a bonus talking point; it’s a procurement requirement. Timber suppliers increasingly provide chain-of-custody documentation, while some manufacturers substitute formaldehyde-based resins for lower-VOC alternatives. When disposal eventually arrives, steel frames join standard recycling streams and plywood cores can be separated for wood-chip recovery.

Future-Proofing Installations

The performance industry evolves quickly - LED screens grow, automation rigs multiply, and weight loads rise. Choosing panels with headroom in their specification guards against the need for premature upgrades. Edge-mounted accessory tracks also keep options open for the later addition of handrails or self-climbing trusses.

Common Misconceptions of Pro Staging

Not every deck is designed for height adjustment. A single panel might sit on fixed legs one day and on a rolling wagon the next, yet the panel itself typically remains at a constant thickness. Mixing adjustable leg systems with panels that lack suitable inserts risks uneven joints and compromises load certification. Where height variability is essential, dedicated solutions exist and should be sourced to match.

Purchasing Pathways

Manufacturers sell direct, through regional dealers, or via production-service houses that maintain stock for rental as well as sale. Each route offers different lead times and after-sales support. Decision-makers often weigh the following:

- Discount levels for bulk orders.

- Availability of replacement surfaces as separate items.

- On-site demonstration or training packages.

- Delivery logistics, including tail-lift or forklift unloading options.

At-a-Glance Advantages

- Consistent structural integrity across entire assemblies.

- Surface choices ranging from paint-ready to aggressive grip.

- Rapid, tool-light setup thanks to integrated locks.

- Options for compact stage deck models where space is limited.