Aluminium Truss

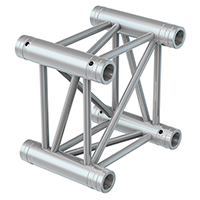

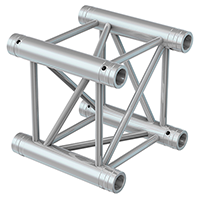

Aluminium truss sits at the centre of most modern stage and event builds. The framework supports lighting, sound equipment, scenic elements, and temporary architecture in venues of every size. Ground personnel favour aluminium trussing for its modest weight, reliable strength, and straightforward handling. When crews must install equipment quickly and remove it just as fast, lightweight aluminium truss proves invaluable.

Material Advantages

Plain aluminium offers a mix of features that traditional steel cannot match in mobile production environments. A concise summary appears below:

- High strength-to-weight ratio – reduced self-weight allows longer spans without excessive support.

- Corrosion resistance – a natural oxide layer shields the metal, permitting repeated outdoor use.

- Thermal conductivity – even heat distribution limits hot-spot damage when high-intensity lamps are mounted.

- Recyclability – components often re-enter the production cycle at end of life, shrinking environmental impact.

- Aesthetic appeal – a clean, brushed finish complements industrial and contemporary interior designs.

Common Applications

Lightweight aluminium truss appears in countless live and fixed installations:

- Concert and theatre stage frameworks

- Rigging points for moving head fixtures, projectors, and line-array speakers

- Exhibition halls and temporary showrooms

- Retail window displays and pop-up stores

- Sporting presentations, award ceremonies, and televised broadcasts

- Architectural ornamentation where non-load-bearing features require a slim profile

Design Options & Configuration

Manufacturers supply ladder truss, triangle truss and quad truss straight sections, curve modules, and custom nodes that create virtually any plan shape. Project requirements tend to follow one of three patterns:

- Linear runs – direct spans bridging two points with minimal joints.

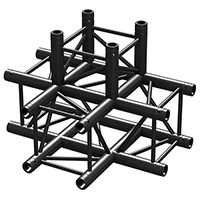

- Grids – intersecting chords forming ceiling arrays or overhead platforms.

- Multi-level structures – stacked bays delivering height for signage or scenic pieces.

Mixing these elements enables towers, gantries, gateways, or more complex sculptural forms without revising standard load tables.

Handling and Assembly Practices

Correct procedure protects both personnel and equipment:

- Visual inspection of tubes, weld seams, and connecting hardware prior to each build.

- Use of non-marking slings and padded corners when transporting finished assemblies.

- Sequential tightening of fasteners to manufacturer torque values, limiting uneven stress.

- Deployment of chain hoists or manual winches for controlled lifts.

- Secondary safety devices, such as steel safety cables, whenever objects hang above occupied zones.

Maintenance Schedule

Preventative care extends service life and preserves load capacity:

- Post-event cleaning with mild detergent and soft cloths; solvents remain unnecessary in most situations.

- Dry storage in racks that support the full length of each segment, avoiding point loading.

- Replacement of worn spigots, pins, or bolts at the first sign of deformation.

- Annual non-destructive testing for heavily travelled touring stock.

Integration with Technical Systems

Aluminium truss must coexist with lighting bars, audio clusters, and cable runs. Project planners often adopt the following measures:

- Pre-rig lighting ladders or drop bars to speed focus periods.

- Purpose-built cable bridges to separate power and signal lines during long spans.

- Built-in hoist pick-up points for incremental height adjustment after final focusing.

- Outriggers or ballast plates when free-standing assemblies carry asymmetrical loads.

Popular Accessories

A concise list of supplementary items illustrates the modular nature of aluminium trussing:

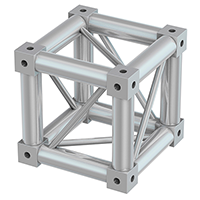

- Base plates for ground-supported towers

- Corner cubes and adjustable blocks for compound angles

- Clamps rated for dynamic loads during live performance

- Flight cases fitted with foam inserts to minimise transit abrasion

Summary

Aluminium truss provides a practical answer wherever temporary or semi-permanent support frames are required. Weight savings reduce labour demands, while corrosion resistance broadens outdoor possibilities. Thoughtful design, correct handling, and regular inspection protect both the asset and everyone working beneath it. By choosing an appropriate specification and following the recognised standards, production teams gain a versatile platform that adapts to each new creative brief.